Cold chain: wireless temperature data loggers make cold chain transport easy

Temperature monitoring solutions for Pharma and Healthcare

In the cold chain, billions of products are transported all day, every day. However, it is a major global challenge to protect temperature-sensitive goods from manufacturer to end-user. Nowadays, pharmaceutical companies distribute millions of vaccines throughout the cold chain in the fight against COVID-19. These vaccines need to be real-time temperature monitored. At SenseAnywhere, we offer an effective temperature monitoring solution with our AiroSensor, proving that cold chain transport can be made easy. Our wireless data loggers ensure the safety and protection of all temperature-sensitive goods.

The beginning of the cold chain

Right from the start, products need to be kept safe within the right environment to preserve their effectiveness and usage. This means that directly after producing, conditions must be met. Therefore, storage rooms and refrigerators offer a solution to maintain products long before shipping or transporting them. The wireless data logger we call AiroSensor can immediately prove its worth since it allows measurements from -30˚C up to +70˚C.

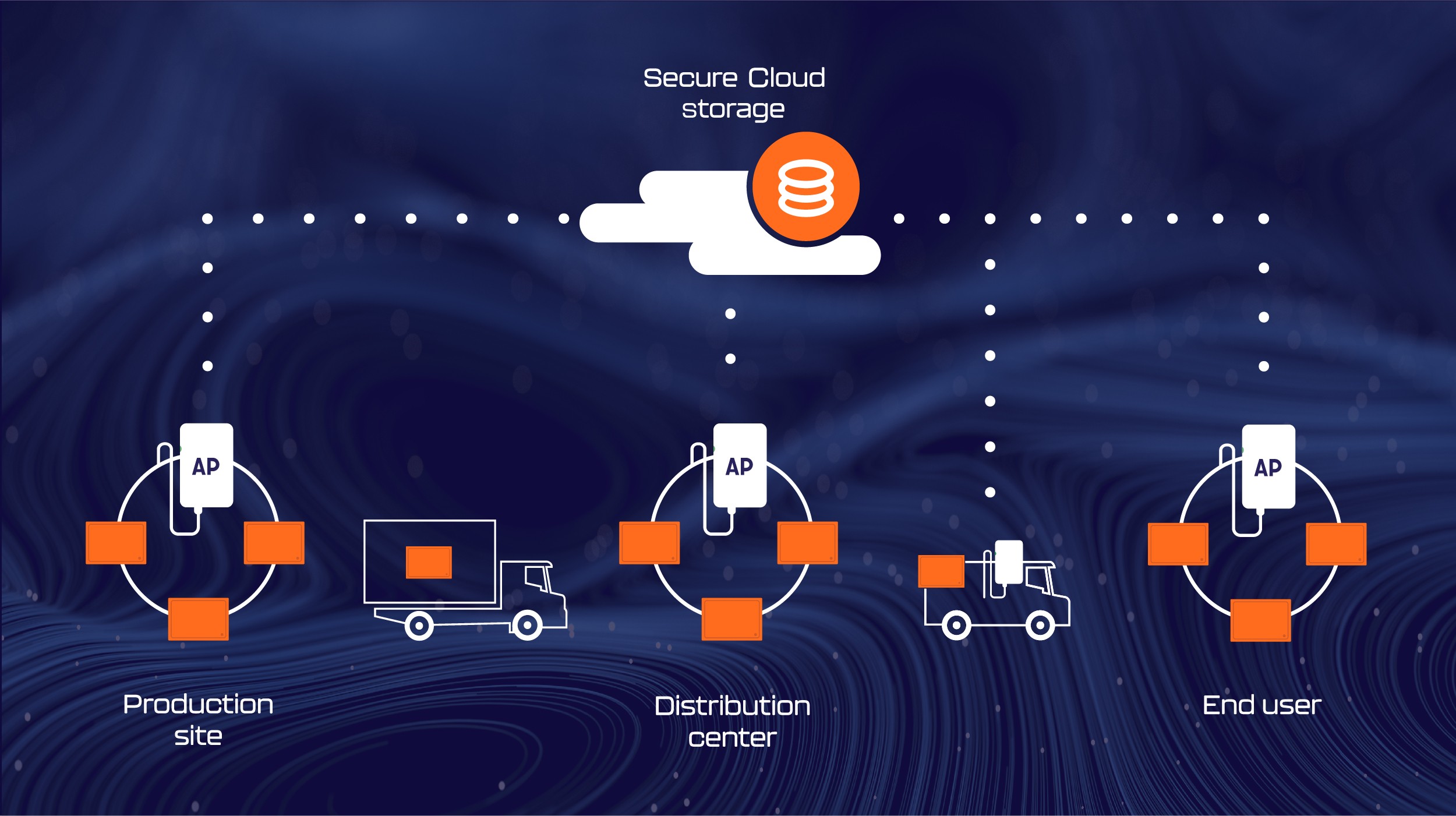

The AiroSensor allows for continuous measuring without having to recharge or replace the battery in a decade. This is because of our unique implemented technology, enabling the battery to have a 10-year lifetime and allowing up to 1 million measurements. After connecting the products wirelessly to our AccessPoint, the AiroSensor will automatically collect all temperature data and send it to our safe and secure Cloud storage location. In addition, all data is transmitted wirelessly and automatic, leaving no room for human error during cold chain transport.

Real-time monitoring data in cold chain transport

To get a direct insight, all gathered data will be available from anywhere, anytime, using any smart device. This is one of the most significant benefits, enabling access to all measured data in a blink of an eye. Because of this, our wireless data loggers are valuable tools in cold chain transport. By installing our AiroSensor, temperatures during cold chain transport can be monitored from start to end. Therefore, any fluctuations can be easily detected and taken care of, ensuring the right conditions for all valuable goods. Indirectly, this prevents health risks and high costs due to spoilage and loss of effectiveness.

But how does it work? In the case of cold chain distribution, the AiroSensor 43 is the best product to get the job done. The external Pt100 Probe can be attached to this model, after which it allows temperature measuring from -200˚C up to 200˚C. Thereby, the probe itself is placed under extreme conditions while the AiroSensor can safely transmit data to our Cloud storage environment. No data will be lost, even when the AiroSensor is out of range of an AccessPoint during cold chain transport. This is mainly because the wireless data logger stores data and will transmit it once it is in range again.

Powerful connectivity using seamless roaming

At SenseAnywhere, we have implemented seamless roaming for all our products in cold chain transport. This means that whenever an AiroSensor comes within range of a SenseAnywhere AccessPoint, a connection automatically establishes. From that point, all gathered data would be securely and safely transmitted to our Cloud storage.

It does not matter to whom the designated AccessPoint belongs. The AiroSensor sends encrypted messages that are not accessible or visible to the owner of the AccessPoint, only to the user of the wireless data logger. In addition, all data loggers and AccessPoints we have active in the field function as our network. This smooth monitoring solution allows continuous measurements without any data loss throughout the cold chain.

Introducing alarms to eliminate the element of surprise

With many miles of transportation needed to deliver products all over the globe, nothing is more frustrating when parameters are exceeded, especially when this is concluded afterwards. Therefore, pre-set alarms are integrated into our software to allow immediate intervention when parameters are exceeded during cold chain transport. By using alarms, users get instantly notified by SMS or email when the products are out of range of the right temperatures.

To achieve this possibility to intervene when needed, the SwitchHolder is created by SenseAnywhere. This product holds the AiroSensor in transport and can be switched “on” and “off”. When switched on before transport, users get a notification when parameters are exceeded. In addition, alarms can be switched off directly at the end of the cold chain transport, so no unnecessary messages are sent out.

Effective data logger in the cold chain

Cold chain transport is a huge global undertaking. Nevertheless, the AiroSensor can tackle this problem. Thanks to the wireless gathering of all measurement data, our software can collect and store this information. Even better, users are allowed to get direct insight into the findings of the data logger. This means that when logged upon our software, users can download a fully documented timetable of all measurements within the cold chain. This can be done individually per AiroSensor or by comparing it with the data of other installed data loggers.

In addition, no human needs to check the temperatures of environmentally sensitive products manually. Think about medicines or vaccines that need to be continuously monitored during cold chain distribution. We have taken measures in our own hand by ensuring no data loss will occur by using our software. This is thanks to our collaboration with the Cloud-based service Microsoft Azure. They are keeping data triple stored on different servers. Simply put, in case one server fails, two others will keep the precious data safe.

Full documentation and accreditation

In addition to our flagship AiroSensor, SenseAnywhere puts a lot of effort into delivering quality and proof of quality needed within the cold chain. Our system enables you to set up and implement a GxP compliant temperature monitoring solution. We fully comply with ISO9001 (Quality Management) and ISO 27001 (Information Security Management). Moreover, we are on track to get the ISO17025 accreditation, which recognises our expertise and competence to (re)calibrate our products.

Also, we offer complete documentation that is needed for organisations operating in a regulated environment. Operating businesses within pharmaceutical industries and Medical devices are compelled by the FDA to instigate a formal validation process. To comply with these requirements, SenseAnywhere offers the Design Qualification (DQ), Manufacturer Software Validation (MSV) and the IQOQ Documentation set. This will allow any business to get the right validations for their line of work in cold chain transport.

Practical and trustful calibration

Another way to prove our qualifications is through ISO17025. This shows our competence to (re)calibrate our products such as AiroSensors and Pt100 probes. At this point in progress, we already comply with the international standard NEN-EN 12830, meaning our calibration complies with the International Quality Standard and is highly accurate.

Since we value our calibration process, we created an alternative product at SenseAnywhere that will allow users to keep measuring data, even while the AiroSensor is sent back for calibration. We call it the AssetTag. This accessory allows for hot-swapping our wireless data loggers. This means one data logger can be replaced instantly by another AiroSensor, continuing measurements in cold chain transport without any data loss. The new activated AiroSensor will start immediately where the other data logger stopped. It is a simple matter of plug-and-play and therefore could not be more user friendly.

Meeting all demands for cold chain transport

In conclusion, we at SenseAnywhere strive to let quality, accuracy and effectiveness be our guideline in cold chain transport. In complementation of our AiroSensor, we developed many accessories to allow our products to measure everything under all circumstances within the distribution of sensitive products across the globe from start to end-user. Currently, we even help monitor vaccines in the cold chain during their distribution throughout Europe. More than tens of thousands of data loggers are used to ensure the effectiveness and quality of vaccines so that vaccination programmes are not delayed.

If you want to use our product for storage or cold chain transport monitoring, our products are easy to install, ready to use and highly rewarding for their task. Stop monitoring manually within the cold chain today and let SenseAnywhere do the monitoring for you so that your goods are delivered safe, sound and above all untouched from the moment they were developed to the moment they arrive at their final destination.

About us

SenseAnywhere manufactures very accurate, easy to use, and long-lasting data loggers, enabling fully automated temperature monitoring during storage or transport of temperature-sensitive products. Our monitoring and mapping solutions are being used in all kinds of industries, among which are Food, Pharma and Logistics, all over the world. Our data loggers have a 10-year battery life, which is unique in the industry.

Read our fully optimised PDF-version of the article.

Subscribe to our newsletter

and stay updated on the latest developments